Induction Heating: What It Is, How it Works","rh":"gh-ia. Een andere afbeelding meldenMeld de aanstootgevende afbeelding. This project is really simple, and surprisingly effective at heating metals using high frequency magnetic fields. The induction heating process heats the material without touching the heat source. I have put together an extensive tutorial at.

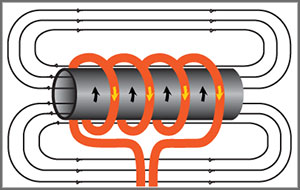

Induced eddy currents heat the workpiece. It uses high frequency electricity to heat materials that are electrically conductive. Simply stated, induction heating is the most clean, efficient, cost-effective, precise, and repeatable method of material heating available to the industry, today.

Inductoheat uses electromagnetic induction heating for applications across multiple industries. Please input information about your induction heating application. CEIA offers the Power Cube Family, a comprehensive modular line of equipment, featuring much-reduced dimensions, ideal for the industrial processes of heat. Systems and solutions for induction hardening, induction bonding, induction brazing, induction tempering, induction annealing.

Learn how our Invisible Heat inductor products, Mini-Ductor & Inductor Series, pay for themselves by cutting torch time in half – and are much safer.

The comprehensive SKF induction heater range can be used for efficiently heating bearings and workpieces, both large and small. RF Heating Consult is gespecialiseerd in induction heating, induction soldering en hard soldering. Wij bieden gespecialiseerde kennis en kunde op maat. Italian manfacturer of workshop equipment, induction heaters, wheel alignment, pulling systems, tig welder.

Learn how Engineers empower chefs with induction heating analysis using an electromagnetic field simulator add-in product for SOLIDWORKS. What is the effect of high frequency on induction heating? Compared to conventional heating technologies, Elotherm induction. With the energy-efficient induction process, heat is generated directly in the workpiece. EMA Indutec GmbH is the center of excellence for inductive heating and hardening plants and frequency converters. Advantages of induction heating: Swift assembly and disassembly; Very suitable for heating work pieces on site; Series of small work pieces can be treated.

In modern industry the requirements for the induction heating process have become.